“Congratulations to Dr. John Payton! Cather Simpson traveled back to the US to attend the successful dissertation defense of her last Ph.D. student from Case Western Reserve University in Ohio.”

“Congratulations to Dr. John Payton! Cather Simpson traveled back to the US to attend the successful dissertation defense of her last Ph.D. student from Case Western Reserve University in Ohio.”

|

|

|

We soon will be expanding the positioning and resolution capabilities of the photon factory by installing an additional X-Y stage from Physik Instrumente (PI). The stage uses PI’s patented NEXACT PiezoWalk technology to achieve high resolution and long travel distances:

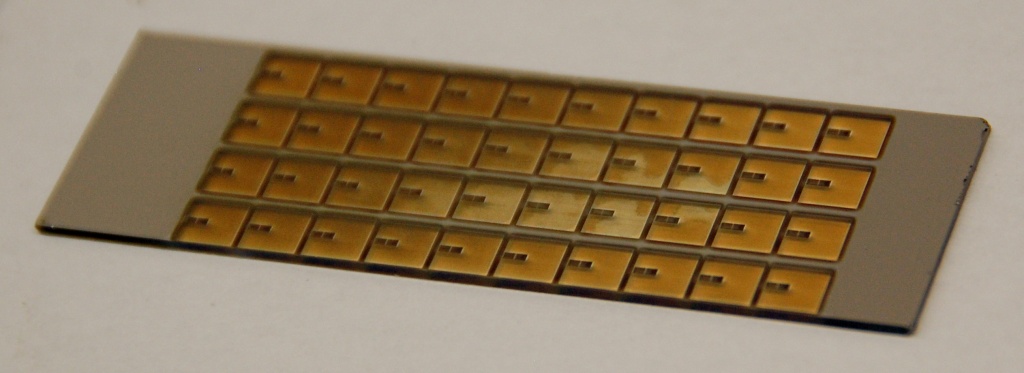

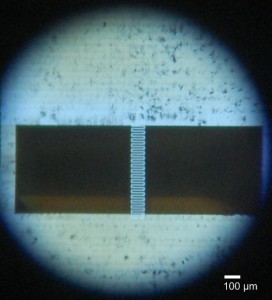

The photo to the left shows the creation of a positive lithography mask, cut using the PF µ-machining system by Cosmin Laslua.The photo illustrates our first attempt to create a new process. Namely, large area removal of a thin film with the excimer laser system. The light brown discoloration shows evidence of a residual chrome dust on the surface of the glass. We are currently investigating ways to improve this process and more thoroughly remove the residual metal. We think this can be accomplished through the addition of processing gas to our µ-machining system or with post machining chemical etch methods available in the new UA microfab. The photo below shows the fidelity of the laser cutting process. The laser cut interdigitated electrodes have a width of only ~ 5 µm. This represents a 1000:1 scale difference between these channels and the the largest (5mm) features in the above picture. This was accomplished with a multilayer CAD drawing and a realignment of the PFµM cutting mask size. You can also see the residual chrome dust coloring the above image in the cleared 5mm x 5mm regions.

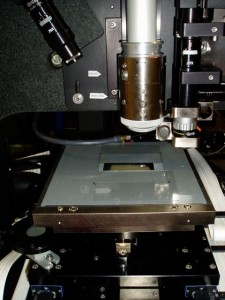

Our first project! Here you can see the JPSA system cutting our first chrome on glass mask for Cosmin Laslua. The small blue spark is the 248nm light fluorescing as a thin layer of chrome is ablated from the surface of the glass microscope slide. This will produce a positive mask, though which light can expose a photoresit.

The JPSA system has been installed and is ready to start cutting! Well I should say that the UV excimer system is ready. The femtosecond system is currently causing some headaches. Primarily, the femtosecond system’s set power (3.3 mJ) and high repition rate (1 kHz) are causing some headaches. We are looking in to ultra-fast variable attenuators from Altechna to address the set output power of the Legend system. The trick here is to lower the power with out streching the pulse. This makes conventaional laser power adjustment with ND filters or polarizers unseable. The Altechna system uses thin film polarizers in combination with half waveplates to minimize the pulse stretching while allowing continuous pulse attenuation.

The inital placement of the JPSA µ-machining platform has been completed. With the arrival of the installation eningeers from JPSA and Coherent Scientific we can begin the final alignement of the Xantos Excimer laser (in the foreground on the labjack) and the Coherent Legend femtosecond laser beam paths. Just getting the system in the door proved to a challenge, but with the removal of a few (probably) insignificant handles we managed to JUST slip it in. We didn’t even need to remove the door frame (a speculation brought up serval times in the past. Thanks for the Peter!

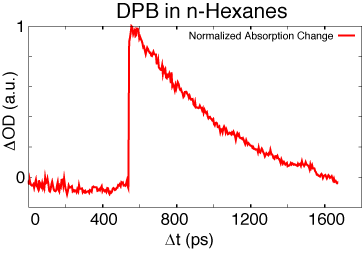

With the PF Legend and TOPAS laser systems installed, we have recently demonstrated our first femtosecond transient absorption experiment. Above is shown the decay of the first excited state of Diphenyl-Butadiene in n-Hexanes, after excitation with a 350nm, ~100fs, pump pulse. For more information, go to the Transient Absorption Spectroscopy pages.

It is truly getting crowded on the factory floor in the Photon Factory. Our new set of optical tables has arrived and are ready to be lifted into place. They are currently in the lab (quite a feat of Kiwi can do attitude. Thanks Steve et al! ) and taking up a lot of space. Soon we will be able to add more capabilities to our lab, including additional nanosecond lasers and another complete amplified laser system. At the moment the tables make for very cool, and hard, beds.

It’s fresh completition at the U of A. The boys over in Ye Ol’ Machine Shoppe have heard of the wonders of our laser cutting expliots, and have decided to join the club. The University of Auckland machine shop has recently aquired a new laser cutter. While the VersaLaser 50 Watt cutting system, does not have as much output power as our 100 Watt Bassel LaserStar system, we anticipate that its large working platform will make it a much more useful general purpose tool!